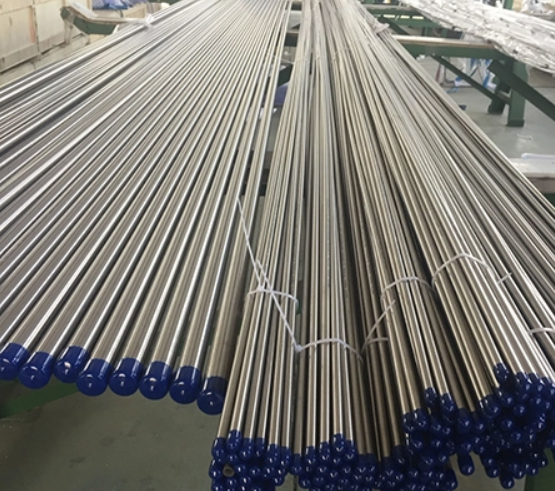

Non-magnetic stainless steel pipes

- Product No.

- 0501-001

- Details:

ZHEJIANG JIEDUN/JIEDV Non-Magnetic Stainless Steel Pipeline

Non-magnetic stainless steel pipelines (often characterized by low magnetic permeability) offer a unique combination of non-magnetism, superior corrosion resistance, high mechanical strength, and excellent machinability. These properties make them indispensable in specialized industrial applications where magnetic interference must be strictly controlled.

1. Precision Instrumentation and Metrology

Housings and Internals: Used for manufacturing enclosures and internal structural components of high-precision instruments such as flow meters, pressure gauges, and analytical balances.

Signal Integrity: Non-magnetic materials prevent interference with sensitive sensing elements, ensuring data integrity.

Electromagnetic Flowmeters (EMF): In EMF applications, non-magnetic conduit prevents magnetic flux distortion, ensuring the accuracy of fluid velocity measurements.

Laboratory Systems: Critical for magnetic stirrer mounting fixtures and high-vacuum (UHV) piping to eliminate stray magnetic fields that could compromise experimental readings.

2. Semiconductor and Electronics Manufacturing

Wafer Handling Systems: Used in wafer transfer pipelines and cleanroom structural frameworks. The non-magnetic nature prevents the attraction of metallic particulates and ensures that ions do not interfere with the photolithography or etching processes.

Cleanroom Integrity: Prevents the magnetic adsorption of dust and impurities, maintaining Class 10/100 cleanliness standards.

EMI/RFI Shielding: Ideal for shielding enclosures in radar and telecommunication base stations. These materials provide structural stability without attenuating or distorting electromagnetic wave transmission.

3. Energy and Power Generation

Nuclear Engineering: Applied in reactor-adjacent piping and heat exchanger components. Non-magnetic alloys minimize eddy current losses in high-strength magnetic fields and withstand the rigors of high-temperature, high-pressure, and high-radiation environments.

Wind Power: Used in sensor protection sleeves for anemometers and tachometers to prevent magnetic interference with rotational speed and wind direction signals, ensuring turbine stability.

4. Security Screening and Medical Imaging

Detection Systems: Used in the structural frames of walk-through metal detectors at airports and transit hubs. Non-magnetic components ensure the detector’s magnetic field remains balanced for the accurate identification of threats.

Medical (MRI) Compatibility: Essential for auxiliary piping (cooling water and gas supply lines) surrounding Magnetic Resonance Imaging (MRI) suites. These pipes are MRI-compatible, ensuring they do not distort the high-uniformity magnetic field required for high-resolution imaging.

5. Advanced Manufacturing and Specialized Engineering

Maglev Infrastructure: Utilized in the auxiliary track structures and onboard fluid systems of Maglev (Magnetic Levitation) trains to eliminate interaction with the powerful levitation magnets, thereby reducing energy dissipation and structural vibration.

Precision Tooling: In injection mold manufacturing, non-magnetic cooling channels prevent the adsorption of metallic scrap or magnetic waste, improving cycle times and surface finish.

Summary of Value Proposition

The primary technical driver for these applications is the mitigation of magnetic interference. By leveraging the low-permeability of these stainless steel grades alongside their inherent chemical resistance and structural durability, engineers can ensure long-term operational stability in the world's most demanding environments.