AS 2129 Flanges for Pipes Valves and Fittings

- Product No.

- FL-AS-2129

- Details:

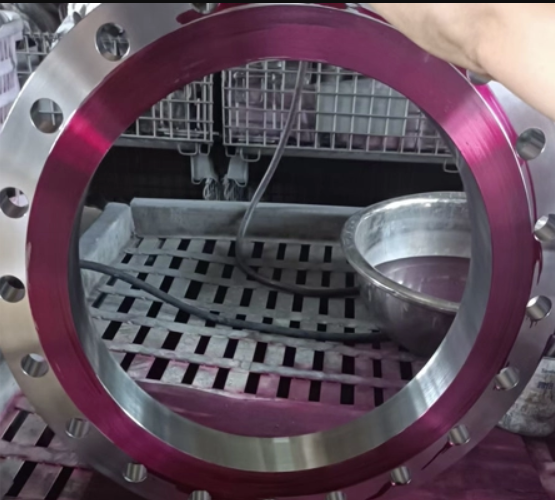

AS 2129 flanges for pipes, valves, and fittings are manufactured via the forging process. Forged construction ensures superior mechanical strength and structural reliability, with key specifications and details as follows:

- Size Range: DN15 – DN3000 (Nominal Diameter, compliant with Australian pipeline size standards)

- Pressure/Connection Series: Table A, Table D, Table E, Table F, Table H, Table J, Table K, Table R, Table S, Table T (each table corresponds to specific pressure ratings, flange types, and connection dimensions per AS 2129)

- Material Scope: Carbon steel, stainless steel (e.g., 304L, 316L, duplex grades), alloy steel (forged to meet AS 2129 material requirements, ensuring corrosion resistance, pressure-bearing capacity, and adaptability to 亚太 regional operating conditions)

- Core Advantages: Forged microstructure delivers excellent sealing performance, high fatigue resistance, and compatibility with Australian and Asia-Pacific industrial pipeline systems—suitable for harsh environments such as chemical corrosion and high pressure.

- Application Scope: Designed for pipelines transporting liquids, particulates, and gases. Widely used in chemical processing, oil refining, boiler systems, power generation, food processing, and other industrial fields requiring standardized pipeline connections in Australian and Asia-Pacific markets.