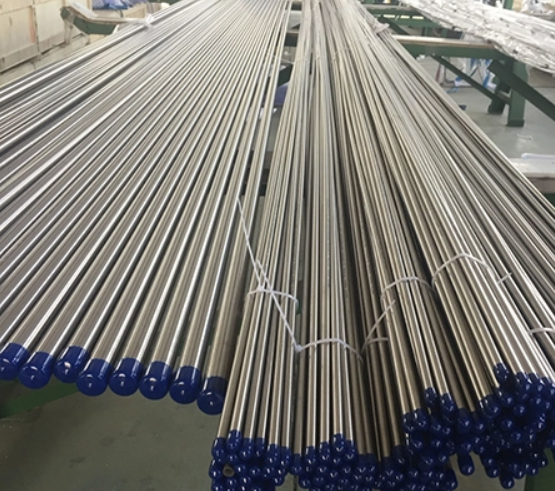

Precision Stainless Steel Tube

- Product No.

- ST-Precision_Tube

- Details:

Precision tubes are high-quality metallic tubes engineered for demanding applications across automotive, aerospace, medical, and industrial sectors. Fabricated with ultra-tight dimensional tolerances and rigorous specifications, they deliver consistent optimal performance. Key characteristics, materials, and applications are as follows:

- Core Characteristics: Ultra-tight dimensional tolerances (e.g., outer diameter/inner diameter tolerance ±0.01mm), superior mechanical strength, exceptional durability, corrosion resistance, and consistent dimensional uniformity—ensuring reliability in high-precision scenarios.

- Material Options: Stainless steel (e.g., 304L, 316L, duplex grades), aluminum (e.g., 6061, 7075), carbon steel (e.g., 1018, 1020), and alloy steel (e.g., 4130, 4340) (selected based on application requirements for strength, weight, corrosion resistance, and temperature adaptability).

- Application Scope:

- Automotive industry: Precision components for fuel injection systems, hydraulic circuits, and transmission assemblies;

- Aerospace sector: Critical tubing for aircraft hydraulic systems, engine components, and avionics cooling lines;

- Medical field: High-precision tubing for surgical instruments, implantable devices, and diagnostic equipment (meets biocompatibility standards such as ISO 10993);

- Industrial applications: Precision fluid conveyance tubes, mechanical parts, and high-precision machinery components (e.g., robotics, automation equipment).