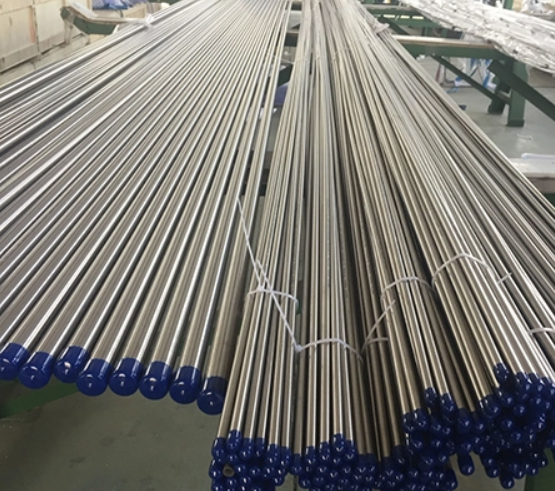

Non-Magnetic

JIEDV Non-magnetic pipelines, valves, and fittings typically use non-ferrous metals like copper, or specific stainless steels (austenitic grades like 304, 316) for environments requiring no magnetic interference, such as MRI rooms, specialized industrial processes, or applications avoiding galvanic corrosion, with options available in various forms like threaded, flanged, and specialized connectors for diverse fluid control needs. Common Materials Austenitic Stainless Steels: Grades like 304, 316, 321, and 347 are predominantly non-magnetic due to their nickel content and crystal structure, offering corrosion resistance. Copper: Naturally non-magnetic and suitable for many water systems. Non-Magnetic Galvanized Seamless Pipe: A specialized steel product designed for non-magnetic applications. Types of Components Valves: Ball valves, check valves, and control valves are available in these non-magnetic materials, sometimes specialized for magnetic resonance imaging (MRI) or sensitive environments. Fittings: Elbows, tees, couplings, flanges, and reducers are made from the same non-magnetic base materials to maintain system integrity. Why They're Used MRI/Medical Fields: Essential where magnetic fields would interfere with imaging equipment. Corrosion Prevention: Avoids galvanic corrosion when connecting dissimilar metals, protecting the system. Sensitive Processes: Used in New Energy, water treatment, and chemical processing where metal contamination or magnetic fields are a concern. How to Identify Magnet Test: Non-magnetic materials will not attract a magnet (e.g., copper, 304/316 stainless); magnetic materials (like some steels) will.